What is Industrial Yarn (IDY) and Why It’s the Future of Technical Textiles

In an era driven by innovation and high-performance fabrics, Industrial Yarn, also known as IDY, is emerging as a crucial material for technical applications. Unlike apparel yarns, IDY is engineered for specific functionality where strength, durability, and reliability matter most.

Defining Industrial Yarn (IDY)

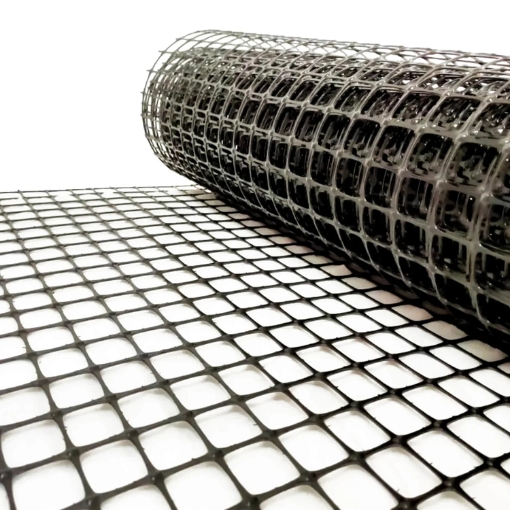

Industrial yarns are polyester-based filament or textured yarns designed not for softness or drape but for structural and functional use. These are widely used in applications such as lifting belts, seat belts, conveyor webbing, geotextiles, hoses, sewing threads, and specialized industrial fabrics.

Global Market Outlook

- The global industrial yarn market was valued at approximately USD 4.34 billion in 2023, and is projected to reach USD 5.98 billion by 2030, growing at a CAGR of 4.7%.

- Asia-Pacific leads the market, accounting for around 37% of global demand, driven by manufacturing hubs in China, India, and Japan.

- Globally, polyester-based industrial yarns dominate due to their strength, stability, and ease of customization especially in tire, infrastructure, and technical textile applications

India’s IDY Landscape

- India stands out in Asia-Pacific textile production—not just in volume but increasing technical yarn output. From 77.7 lakh tonnes in 2014–15, total yarn production surged to 97.5 lakh tonnes by 2022–23— enabling better supply of both apparel and industrial yarns.

- As the second largest exporter of textiles globally, India contributes approximately 9.2% of global synthetic yarn exports, including IDY, placing it behind only China and Turkey in synthetic yarn trade value.

- Export opportunities are unfolding rapidly in India’s technical yarn segment like IDY, supported by policy pushes and rising industrial fabric demand.

Why IDY Is Gaining Strategic Importance

- Industrial Performance : IDY delivers high tensile strength, low elongation, and chemical resistance—critical for automotive, aerospace, and infrastructure uses.

- Customizable Properties :Manufacturers can tailor denier, twist, and finish, making IDY versatile for diverse industrial use-cases.

- Sustainability & Traceability : Recycled polyester variants and certifications such as GRS and ISO align IDY with global ESG standards—supporting circular economy goals.

- Economic Opportunity : Growth in technical textile demand, combined with favourable exports and Free Trade Agreements, positions IDY as India’s next textile growth vector.